Laser Cut and Press Brake

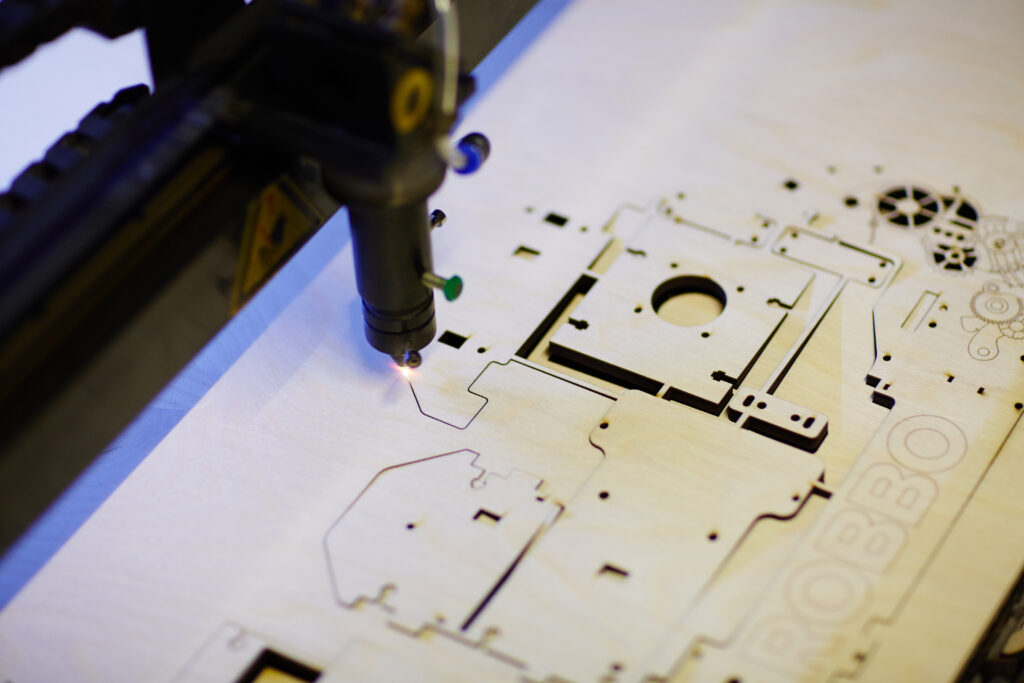

We operate two 3-axis laser cutting machines in tandem with material stacking facilities, capable of running 24 hours a day, seven days a week. These machines feature a robust 9KW power rating and incorporate the latest cutting-edge technology.

Laser cutting: Our automatic tower solutions encompass the seamless loading and unloading of sheets to and from the laser machines, along with the storage of both raw materials and finished sheets. This system optimises laser utilisation while enabling the handling of various material types, including steel, aluminium, and stainless steel, through the use of suction cups. The tower storage system offers a modular configuration, allowing users to customise the number of pallets for raw materials and stacking.

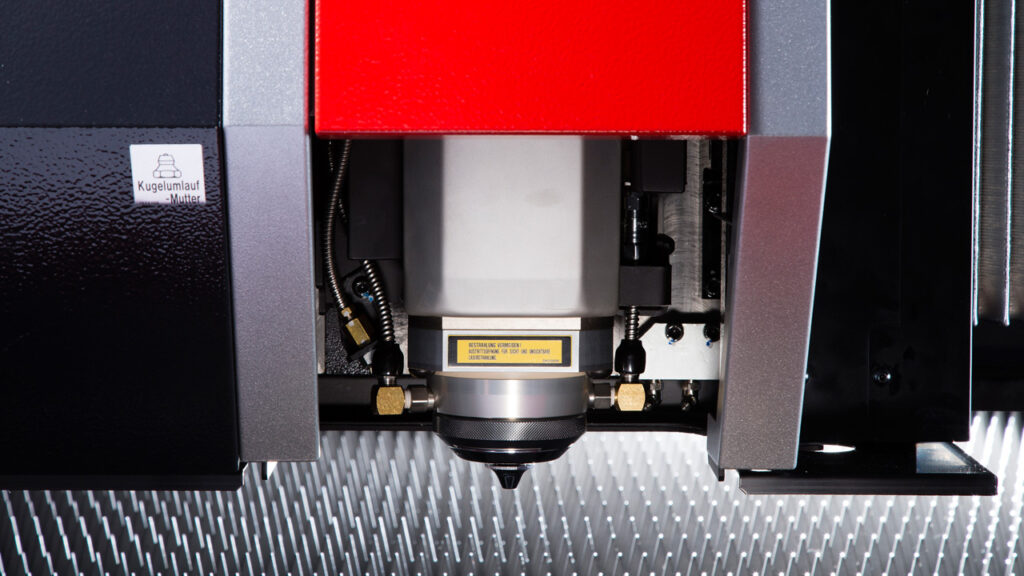

The 9KW laser head delivers precision cutting for materials up to 20mm thick. It also provides the option to use Oxygen and is equipped with our in-house Nitrogen generator, making it suitable for cutting most metals. Additionally, the 9KW AMADA Auto Collimation system ensures unrivalled laser beam spot control, while AMADA’s Variable Beam Control technology adjusts the laser mode, enabling the processing of different materials and thicknesses with a single cutting lens.

This system ensures high-quality results and efficient processing, particularly for medium to thick materials and very high-speed piercing.

Our laser cutting capabilities are complemented by a trio of Amada Press brakes, offering a range of press brake machines with various technologies, sizes, and tooling options. This diversity allows us to provide tailored solutions to meet your specific goals.