Manufacturer of Engineered Products & Fabricated Assemblies

Founded in Britain

Exporting globally since 1920

Clydesdale Engineering,

An Engineering led business that manufactures componentry for Off Highway, Automotive & Defence Customers. Clydesdale Engineering offer a breadth of complimentary core skills supporting customers with a range of products from pressings to complex assemblies and fabrications.

Automotive & Defence Supplier

Engineering

From concept design, analysis and prototype vehicle builds, through to production volumes for OEM car build programmes.

Supplier to Automotive, Off Highway & Defence Industries

Offering proprietary components & manufacturing customer designed products

Clydesdale Engineering and its trading divisions:

As the markets have changed the business has adapted and invested in alternative technologies to meet with the changing face of the customer requirements. This has led to investing in laser cutting technology along with the associated downstream press brake processes.

Recognising the growing desire for repeatability, cost control and quality standards, further investment in Progression presses and robot welding facilities means that Clydesdale Engineering can remain competitive in a challenging market.

Clydesdale Engineering’s key assets are its people and the approach and support it gives its customers.

- Aiming to constantly improve and adapt.

- Customer focused with dedicated project management.

- Flexibility to adapt and change to markets and customer requirements.

- Ensuring the working environment is a safe and enjoyable place to be.

Our Vision & Mission

Empowering businesses to thrive with tailored strategies. Our mission is sustainable growth through innovative solutions and manufacturing.

Recognition

Celebrated for excellence in Engineering, Manufacturing, acknowledged for empowering clients with innovative solutions and transformative results for over 100 years.

Our Services

What we do

Anti-Vibration Dampers »

Anti-vibration and shock isolation mounting solutions for military, marine, aerospace and commercial applications.

Laser Cutting and Press Brake »

Precision laser cutting service with 24hour capability supported by a family or press brakes with 3m beds giving the capability to manufacture product without traditional press tools.

Fabrications & Robot Welding »

Complex fabrication, a combination of tube bending, bracketry, nut welding all welded via one of Clydesdale Engineering’s robot cells.

Levers and Pedals »

Pedal arms, Pedal boxes, Hand brakes, foot brakes, bespoke designs or select something from Clydesdale Engineering’s product range to suit your requirements.

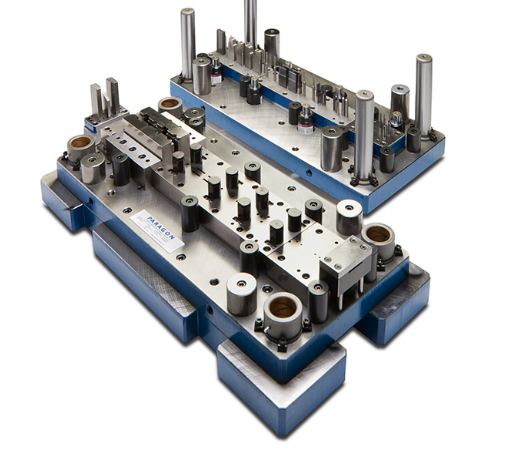

Progression and Manual Pressings »

With over 40 presses in the Clydesdale Engineering press hall, a combination of manual presses complimented with progression allows Clydesdale Engineering to support any volume project requirements.

Composites »

Manufacturing carbon fibre products for the automotive sector or support specialist product into the printing market Clydesdale Engineering have the core team to deliver a quality product.

The Clydesdale Engineering Team

Over many years it has become obvious that investing in the employees of the business gets rewards and makes for a better working environment.

Be it new apprentice schemes, additional training or simply listening to ideas and suggestions, taking them forward and implementing changes demonstrates to the business that Clydesdale Engineering care. The people are the cogs of the business, deserve recognition for their efforts and idea which creates a foundation for an effective team.